Electro Galvanization

Electro Galvanization is an anti-rust coating method. The main purpose of coatings is to prevent rust (corrosion). Galvanizing can be done with two different methods.

- Hot Dip Galvanized coating

- Electro Galvanized coating

In the galvanizing process by hot dipping method, the life of the metal material is extended by approximately 30 years. It may be preferred in some cases because it is more economical.

Electro galvanized coating method is a method of coating metal material with processes based on electrochemical reaction. Much higher quality results can be obtained. After electro-galvanized coating, the properties of the material do not change and it can be welded. Post-welding is not very healthy in the hot dipping method.

Electro Galvanized coating is made with pure Zinc (ZN). The alloy is not made with zinc.

In your Electro Galvanized coating, the coating never separates from the metal; it becomes a part of the coated metal as a result of the electrochemical reaction.

Thanks to our Electro Galvanized tanks of 730 cm length, 150 cm width and 150 cm depth in our company, Electro Galvanized process can be applied to all our products before or after production.

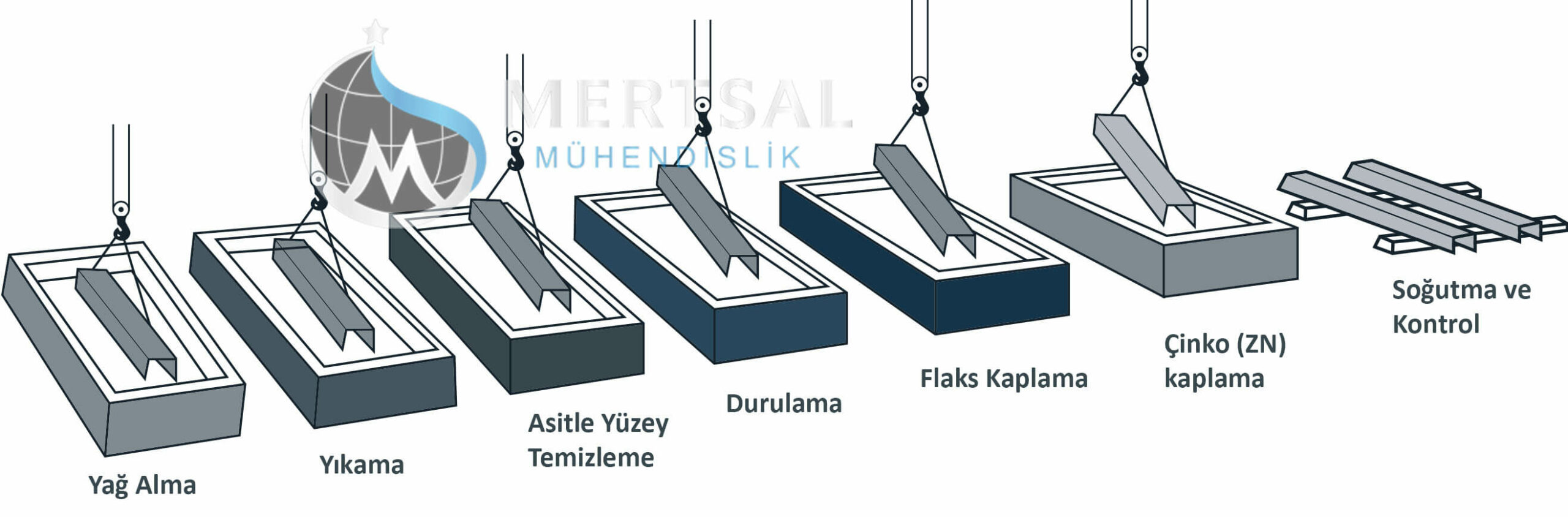

Galvanizing Process

Galvanizing and Painting

Electro Galvanizing Pool

Galvanizing Line Galvanized Wire Mesh

Top View of Galvanizing Line

Electro Galvanized Wire Mesh